Home / Products / Brown Fused Alumina / 1050 Calcined Brown Fused Alumina For Coated Abrasives

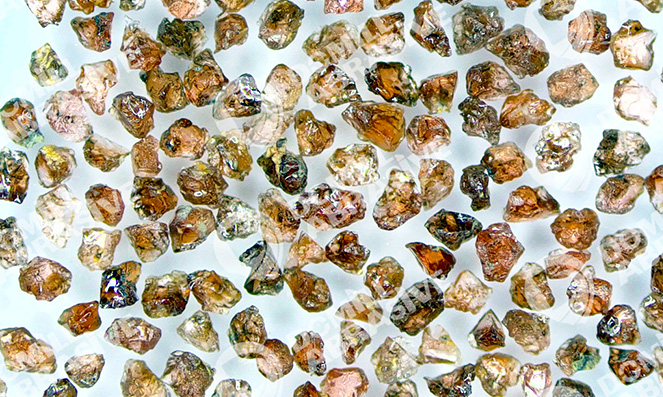

1050 Calcined Brown Fused Alumina (CBFA) is a premium abrasive material made by calcining high-quality brown fused alumina at 1050°C. The calcining process increases particle toughness, reduces impurities, and improves bonding properties, making it ideal for coated abrasive applications such as sandpaper, belts, and wheels.

Increased toughness: The calcining process improves particle characteristics, reducing brittleness and increasing resilience.

Improved bonding: Adheres better to resin and cloth substrates, increasing product durability.

Thermal stability: Performs well in high friction applications and will not degrade at high temperatures.

Sharp, angular particles: Provides aggressive cutting action for superior material removal.

Consistent quality: Uniform particle size, reduced impurities, and predictable performance.

Sandpaper: Ideal for wood, metal, and composite sanding.

Belts: Provide efficient material removal for heavy-duty applications.

Flap sanding discs: ensure high performance in grinding and finishing.

Sandpaper: provide consistent surface finish for precision tasks.

Sponge sanding blocks: suitable for flexible abrasive applications on curved or irregular surfaces.

AT22 is sharp, low bulk density, better than A22. The coated abrasives made by AT22 are sharp, with good heat dissipation effect and high grinding efficiency. It is for the production of regular coated abrasives, suitable for all kinds of metal and wood hand grinding.

AT25 is angular, medium bulk density, is better than A25. The coated abrasives made by AT25 are sharp, can be used in making mid-range abrasive cloth, sandpaper, sanding belts, machining of low carbon steel, steel alloy, and hard wood.

GRITS AVAILABLE:P12-P2500

Customized sizes available upon request please refer to the TDS document below.

Please fill out the form.We will reply you in 24 hours.