Home / Products / Brown Fused Alumina / 1350 Calcined Brown Fused Alumina For Bonded Abrasives

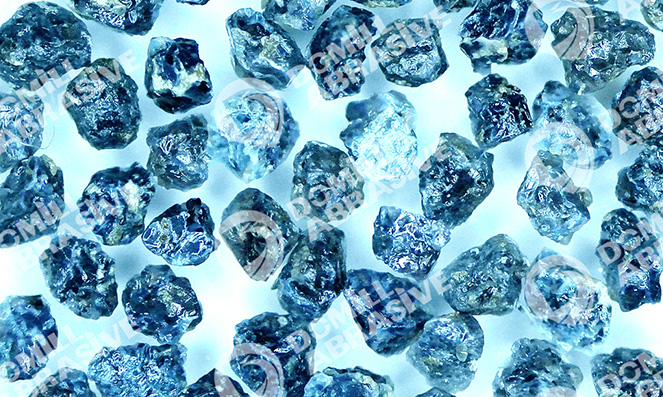

1350 Calcined Brown Fused Alumina (BFA) is a high-purity abrasive material produced by calcining high-grade brown fused alumina at approximately 1350°C. This calcination process eliminates residual stress, reduces internal porosity, and enhances the grain's toughness, making it an ideal choice for manufacturing bonded abrasives.

Improved durability and resistance to fracturing under pressure.

Contains minimal impurities, ensuring stable bonding and consistent abrasive performance.

Suitable for high-temperature grinding applications in bonded abrasive tools.

Ensures uniform grain structure for optimal abrasive tool performance.

Provides aggressive cutting action with excellent material removal rates.

Grinding Wheels: Used for precision cutting and grinding in industrial applications.

Cutting Discs: Suitable for cutting hard materials such as metals, stones, and composites.

Sharpening Stones: Provides a fine finish for sharpening tools and blades.

Mounted Points: Ideal for detail work and precision grinding tasks.

For example, AB12 is suitable for producing sharp 400 diameter casting cutting discs. (F24) 180-230 diameter industrial grade grinding discs, added as auxiliary materials to zirconium corundum SG abrasives. (F24, F30)

AB12 is sharp, low bulk density, great self-sharpening ability, better than AT12. It is suitable to make top-grade bonded abrasives, with fast cutting and high grinding ratio, machining of low carbon steel, steel alloy and stainless steel.

AB18 is blocky, high bulk density, better than AT18. Reduce expansion and black specks on vitrified abrasives. Improved durability makes them suitable for making top-grade bonded abrasives in heavy-duty machining and double-disc cylindrical grinding.

GRITS AVAILABLE:F4-F800

Customized sizes available upon request please refer to the TDS document below.

Please fill out the form.We will reply you in 24 hours.