Home / News & Blog / Abrasive Blog / Why is Aluminum Oxide Used on Sandpaper?

Sandpaper is an indispensable tool in various industries, from woodworking to automotive, and even in household projects. While sandpaper can be made from different abrasive materials, aluminum oxide is by far the most common. But why is that? What makes aluminum oxide such a popular choice for sandpaper? In this article, we’ll delve into the specific qualities of aluminum oxide, why it’s preferred over other materials, and how it contributes to more effective and durable sandpaper.

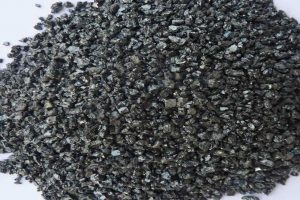

Aluminum oxide (Al₂O₃) is a chemical compound made up of aluminum and oxygen. It occurs naturally as the mineral corundum and is refined for industrial purposes. This compound is known for its hardness and strength, making it an ideal abrasive material. When applied to sandpaper, aluminum oxide is able to sand down surfaces smoothly and efficiently without breaking down quickly.

Key Properties of Aluminum Oxide:

Durability: Aluminum oxide is long-lasting and does not easily break down during sanding, offering extended use.

Self-Sharpening: It fractures in a way that exposes new, sharp edges, maintaining the abrasive quality over time.

Hardness: With a Mohs hardness rating of 9, aluminum oxide is one of the toughest substances, second only to materials like diamonds.

a) Versatility Across Different Materials

One of the primary reasons aluminum oxide is used on sandpaper is its versatility. It works on a wide range of materials, including wood, metal, plastic, and paint. For industries like woodworking, where various surfaces need to be smoothed or shaped, aluminum oxide offers consistency in performance.

For instance, woodworkers might start with coarse-grit aluminum oxide sandpaper to remove rough patches from a wooden surface, then gradually work their way to a fine-grit version for a smooth, polished finish. The adaptability of aluminum oxide means it can be used on soft woods as well as hardwoods, and even in sanding finishes like varnish.

b) Durability and Longevity

Aluminum oxide’s durability makes it an economical choice for sandpaper manufacturers. Its self-sharpening nature ensures that the abrasive maintains its effectiveness throughout multiple uses. When aluminum oxide grains fracture during the sanding process, they break into smaller, sharp particles that continue to remove material efficiently. This self-renewing quality extends the life of the sandpaper, reducing the need for frequent replacements.

For professionals and hobbyists alike, this longevity means lower costs and less hassle. Users do not need to replace the sandpaper as often, which is a crucial factor in industrial applications where time and material costs are critical.

c) Heat Resistance

Another important aspect of aluminum oxide is its ability to withstand high temperatures. During the sanding process, friction between the abrasive and the workpiece generates heat. Some abrasives can break down or lose effectiveness when exposed to heat, but aluminum oxide retains its abrasive properties even under high temperatures. This feature is particularly beneficial when sanding metals or in high-speed applications, such as belt sanders or rotary tools, where overheating can be a concern.

Heat resistance is also essential in automotive and metalworking applications, where high-performance abrasives are required to handle tough materials like steel, iron, and aluminum without losing their cutting power.

While aluminum oxide is widely used, it’s not the only abrasive available for sandpaper. Other common materials include silicon carbide, garnet, and zirconia alumina. Let’s compare how aluminum oxide stacks up against these alternatives:

Silicon carbide is sharper than aluminum oxide, making it suitable for applications that require rapid material removal, such as grinding glass or plastic. However, its sharpness comes at a cost—silicon carbide wears out more quickly. Unlike aluminum oxide, it doesn’t have a self-sharpening property. For projects that require long-lasting sandpaper, especially on wood or metal, aluminum oxide is often the better option.

b) Garnet

Garnet is a natural abrasive material commonly used in woodworking. While it delivers a fine finish and is ideal for hand sanding, it’s not as durable as aluminum oxide. Garnet sandpaper tends to wear out faster, making it more suitable for smaller, less intensive tasks. For large-scale projects or more abrasive tasks, aluminum oxide sandpaper is the go-to option due to its toughness and longevity.

Zirconia alumina is another tough, durable abrasive often used for high-pressure grinding and sanding. It’s typically employed in industrial settings where aggressive material removal is required. While zirconia alumina offers excellent performance in heavy-duty applications, it can be overkill for less demanding tasks. Aluminum oxide provides a balanced solution, delivering both durability and versatility at a more affordable price.

Aluminum oxide sandpaper comes in various forms, each tailored to specific applications. Here are some of the most common types:

a) Coated Aluminum Oxide Sandpaper

This is the most common form of aluminum oxide sandpaper, where abrasive grains are adhered to a backing material (such as paper, cloth, or a combination). The backing type determines the flexibility and strength of the sandpaper, making coated aluminum oxide versatile for both hand sanding and power tool use.

b) Hook and Loop (Velcro) Sandpaper

Aluminum oxide is also used in hook-and-loop sandpaper, designed for use with orbital sanders. This sandpaper is easy to attach and remove, making it a convenient option for quick changes between grits during a project.

c) Sanding Belts

For belt sanders, aluminum oxide is commonly used in sanding belts. These belts are designed for high-speed material removal and are perfect for use in woodworking, metalworking, and other heavy-duty tasks. The heat-resistant properties of aluminum oxide make it particularly well-suited for sanding belts, which endure significant friction and heat.

a) Woodworking

In woodworking, aluminum oxide sandpaper is used for everything from rough sanding to fine finishing. Whether you’re shaping wood or preparing a surface for staining, aluminum oxide provides the durability and cutting power needed to achieve smooth, consistent results.

b) Metalworking

Aluminum oxide sandpaper is also ideal for metalworking applications. Its ability to withstand heat and pressure makes it suitable for tasks like rust removal, smoothing welds, and polishing metal surfaces.

c) Automotive

In the automotive industry, aluminum oxide is used to sand paint, primer, and body filler. It offers precise control over material removal, making it easier to achieve a smooth, even surface before painting or finishing.

d) DIY Home Projects

For DIY enthusiasts, aluminum oxide sandpaper is a go-to for tasks like furniture refinishing, cabinet sanding, and even drywall smoothing. Its versatility means it can handle a wide range of materials, making it a practical choice for household use.

Finally, it’s important to consider the environmental and economic impacts of using aluminum oxide sandpaper. While it’s a synthetic material, aluminum oxide sandpaper is durable and long-lasting, reducing waste over time. Its longevity also translates to cost savings for consumers, as fewer sheets or rolls are required for a given project.

Aluminum oxide is the preferred abrasive material for sandpaper due to its durability, versatility, and self-sharpening properties. It can be used across various materials, from wood to metal, and withstands the heat generated by high-speed sanding. Whether you’re a professional in woodworking or metalworking, or just tackling a DIY project, aluminum oxide sandpaper provides the reliability and performance needed for effective results.

With its unique combination of toughness and adaptability, it’s no wonder that aluminum oxide remains the industry standard for sandpaper.