Home / News & Blog / Abrasive Blog / In-Depth Revelation: The Outstanding Performer in Coated Abrasives—Sandcloth

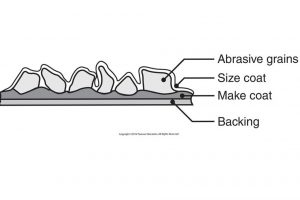

Coated abrasives are also called flexible abrasives. After pretreatment, gluing, sanding, drying, and curing, the coated abrasive substrate is made into large rolls. Cutting, jointing, bonding, and other processes make it into different shapes such as pages, rolls, strips, discs, wheels, etc. to meet the different needs of users. The characteristics of coated abrasives and their performance as grinding and polishing tools are mainly determined by ten factors, namely, substrate type, substrate treatment, abrasive type, abrasive grain size, sand planting density, binder, bond strength, manufacturing process, shape (conversion process) and size. Coated abrasives also have three elements: substrate, abrasive, and binder.

1. Substrate

The substrate is the basic material of coated abrasives, used to carry abrasives and binders. Common substrates include cloth, paper, steel paper, cloth-paper composite, non-woven fabrics, polyester film, etc. Coated abrasives with paper and cloth as substrates account for more than 90% of the entire coated abrasives.

The substrate ranks first among the three elements, which shows its importance. Different substrate materials provide different strength, flexibility, and durability, meeting various needs from precision polishing to heavy grinding. Understanding the characteristics and applicability of the substrate will help to select the appropriate abrasive tool in practical applications, thereby improving processing efficiency and product quality.

2. Abrasive

Coated abrasives often use the P sand standard, and some products that do not require a high range of particle sizes use the F sand standard. GB/T 9258 stipulates the composition and determination of abrasive particle sizes for coated abrasives. There are 28 current P sand standard particle sizes. Among them, there are 15 coarse particle sizes, namely P12, P16, P20, P24, P30, P36, P40, P50, P60, P80, P100, P120, P150, P180 and P220; there are 13 micro powders, namely P240, P280, P320, P360, P400, P500, P600, P800, P1000, P1200, P1500, P2000 and P2500.

3. Binder

Binder refers to the general term for the binders used in the entire manufacturing process of coated abrasives, that is, the general term for all binders that constitute the coated abrasive entity. Including:

As a binder for coated abrasives, such as the base coat, size coat, and super coating;

As a substrate treatment adhesive, such as slurry;

Adhesives used in the conversion process of coated abrasives, such as sanding belt joint glue, and adhesives used in special-shaped products such as sanding wheels, sanding discs, and sanding sleeves.

The quality and use of these adhesives affect the quality of coated abrasives, which is particularly important in the production of large rolls of coated abrasives. For example, the bonding strength refers to the degree of firmness with which the adhesive bonds the abrasive and the substrate, that is, when an external force acts on the surface of the abrasive, the adhesive resists the external force and causes the abrasive particles to fall off the surface. It is similar to the hardness of the grinding wheel, and the abrasive may fall off before being used.

The cloth base is the most widely used, with good softness, high strength, and many types, and must be subjected to strict substrate treatment. The cloth base is usually composed of cotton cloth, polyester cloth, polyester nylon, rayon, and blends of cotton and polyester cloth. Different types of cloth have different weights, strengths, characteristics, and applications. The weights and applications of common clothes are as follows. The abrasive cloth rolls made of these cloths mainly include soft cloth, abrasive belt cloth, and leaf wheel cloth.

1. Soft Cloth

Soft cloth is a type of abrasive cloth. It uses a cloth base material with high flexibility (J-type cloth), which makes the abrasive cloth smoother and more fit when used. Most soft cloths are converted into hand-torn cloth (JB-5), and can also be converted into abrasive cloth products such as octagonal sand, sand sleeves, small sand belts, thousand-thread wheels, and sand sheets that do not require high grinding.

Hand-tear cloth is a type of abrasive cloth used in coated abrasives, typically in roll form. It is generally made of J-weight pure cotton cloth with standard brown fused alumina abrasive and full resin bonding. The grit range is P40-P800. Its main feature is excellent flexibility, allowing it to be easily torn by hand into the desired size without the need for scissors or other tools. It is primarily used for manual sanding or small tools and is suitable for processing workpieces with complex shapes and curved surfaces.

The advantages of hand-torn cloth are easy operation and strong adaptability. It can be cut into strips, blocks, and other shapes according to specific needs. It is widely used in the surface treatment of metal, wood, and other materials.

2. Sanding Belt Cloth

The sanding belt is the most important conversion product of sanding cloth, the substrate of sanding belt cloth has high strength and flexibility, which can withstand the tensile force and high speed when sanding, so it is suitable for continuous grinding processing in industry. Abrasive belt cloth is widely used in deburring, surface sanding, and fine polishing of metal, wood, plastics, and other materials, especially effective in the surface treatment of pipes, plates, and large equipment.

The industry does not have a clear classification for sanding belts, and they are generally referred to as metal sanding belts, woodworking sanding belts, and specialized sanding belts (for plastics and other composite materials). Based on the different substrates used, sanding belt cloth can be categorized into narrow sanding belts and wide sanding belts.

Small and medium-sized abrasive belts or narrow abrasive belts generally use J-type blended fabrics and use ordinary brown fused alumina, calcined brown fused alumina, zirconium fused alumina, stacked abrasives, and silicon carbide according to the application object. Compared with wide abrasive belts, small and medium-sized abrasive belts are smaller in size and are usually used in portable belt sanders or handheld tools. Due to their flexibility and size characteristics, small abrasive belts are suitable for processing various small or complex-shaped workpieces, such as pipes, molds, tools, etc. Small abrasive belts can perform operations such as deburring, surface grinding, and polishing, and are often used for surface treatment of materials such as metals, wood, and plastics. Particle size range: P60-P600.

Wide sand belts are large-sized coated abrasive belts, usually more than 300 mm (about 12 inches) wide, used for industrial-grade continuous grinding. Due to its wide design, wide sand belts can efficiently process the surface of large workpieces, such as metal sheets, wood, stone, etc., providing a uniform grinding effect. It is usually installed on a dedicated wide belt grinder and is suitable for a variety of surface preparation tasks, including deburring, deoxidation, fine grinding, and polishing. Wide sand belts can be used in dry and wet grinding conditions to meet different processing needs.

Cloth-based wide abrasive belts are typically made with X- and Y-heavy-duty cloth, allowing them to withstand higher grinding pressures and high-speed grinding environments. Because of its durability, it is suitable for heavy-duty grinding, deburring, and rough grinding applications, especially in metalworking where large, heavy workpieces are handled. The durability of the heavy-duty cloth makes it suitable for extended industrial production use. Generally speaking, X-blend and polyester cloths are more often used in medium and heavy-duty grinding, while Y-polyester cloths are mainly used in heavy-duty grinding. In terms of abrasive selection, the higher the toughness, the heavier the substrate. Common grit sizes for ordinary brown fused alumina and calcined brown fused alumina are P24-P800, zirconium fused alumina is P24-P120, and ceramic abrasives are P40-P240.

3. Turntable Cloth

Flap cloth is a cloth base material used to make coated abrasives such as flap discs, flap wheels, and flap wheels with handles. Flap wheels are made of multiple layers of abrasive cloth stacked in a fan shape, similar to book pages, hence the name “flap wheel”. Flap cloth usually uses a high-strength, wear-resistant cloth base and a variety of abrasives. This design allows the flap wheel to flexibly contact the workpiece surface when rotating at high speed, making it suitable for applications such as curved surface grinding, deburring, and surface polishing. Flap cloth has good durability and flexibility, and is widely used in the processing of metals, wood, and other materials.

Unlike abrasive belt cloth, flake wheel cloth mainly uses X-type blended cloth. This is because the working principle of the flake wheel is similar to that of the grinding wheel. It is necessary to ensure the efficiency of abrasive use and ensure that the blunt abrasive falls off in time so that the new abrasive can participate in grinding as soon as possible. This requires the base cloth to have a certain cotton content to achieve synchronous consumption. Due to fierce market competition, the abrasives used in flake wheel cloth are becoming more and more abundant, and pure brown alumina flake wheel cloth is becoming less and less. More pure calcined brown fused alumina flake wheel cloth is used, or zirconium fused alumina (Jinniu KX765Z) is added to high-temperature calcined brown fused alumina to make special flake wheel cloth, making it more competitive in the market. The common particle size of louver blades is P50-P80, and the common particle size of chisel wheels is P40-P800.

In conclusion, coated abrasives play a pivotal role in modern industrial and manufacturing processes, offering versatile solutions for grinding, polishing, and surface treatment. Their performance is shaped by critical factors such as substrate type, abrasive material, grain size, and adhesive quality, allowing customization for specific applications. From the flexibility of hand-torn cloth for intricate tasks to the durability of wide sanding belts for heavy-duty grinding, these tools address diverse needs across industries. As advancements in materials and manufacturing techniques continue, coated abrasives will remain indispensable in enhancing efficiency, precision, and quality in material processing.