Home / News & Blog / Abrasive Blog / Types and Selection of Bonding Agents for Abrasives: Ceramic, Resin, Rubber, and Magnesia

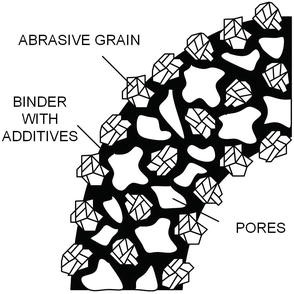

The performance of the binder in abrasives affects its reactivity with the abrasive grains and its strength. When the binder has good reactivity with the abrasive grains, their bonding force is strong, making it less likely for the abrasive grains to fracture or fall off. A high binder strength allows the abrasive grains to withstand higher grinding forces and also enables the grinding wheel to have higher rotational strength, making it less prone to breakage. Furthermore, when the binder reacts better with the abrasive grains, less binder is required for abrasives of the same hardness, resulting in a looser structure that benefits the grinding process.

The selection of the binder for abrasives is primarily related to the machining method, operating speed, and the surface finishing requirements of the workpiece. Each type of binder has its advantages and disadvantages, and the choice of abrasive binder should be based on the specific conditions during grinding.

①Ceramic Binder(V)

This type of binder has the widest range of applications and can be used to manufacture abrasives in various grain sizes, hardness, structures, shapes, and sizes. Ceramic binders exhibit stable performance during grinding, offering excellent resistance to water, acids, alkalis, and oils, and are unaffected by weather or temperature changes. They can be used under a variety of grinding fluid conditions and are also suitable for dry grinding. Compared to other binders, ceramic binders allow the production of abrasives with different pore sizes, such as open-pore wheels and loosely structured wheels. These abrasives are less prone to clogging by chips during grinding, which results in higher grinding efficiency.

When the abrasive, grain size and hardness are the same, and the same workpiece is processed under identical conditions, the wear of ceramic binder abrasives is lower compared to other binders. As a result, ceramic binder abrasives have a longer service life.

Typically, the operating speed of ceramic binder grinding wheels is below 35 m/s. However, high-speed grinding wheels can also be made with speeds exceeding 35 m/s, such as 50 m/s, 60 m/s, 80 m/s, and even 120 m/s.

Vitrified bond grinding wheels can better maintain their shape during the grinding process, so they are suitable for form grinding, such as thread grinding, gear grinding, template grinding, and other forms of grinding.

Boron-containing ceramic binders have better-grinding performance than other types of ceramic binders because they use less binder, which can increase the porosity of the grinding tool accordingly and make the cutting edge of the abrasive more exposed.

②Resin Binder(B)

The usage range of resin binders is second only to ceramic binders. Resin binders have a certain degree of elasticity and sufficient strength, along with polishing capabilities, making them suitable for coarse, fine, and precision grinding. They are generally applicable in the following areas:

Since resin bonds are easy to burn out at high temperatures and have good self-sharpening properties, they are widely used in general or high-speed rough grinding processes, such as deburring castings, grinding steel billets, surface grinding to prevent heat generation, etc. Resin bonds are also commonly used for cutting metal materials or non-metallic materials, such as thin-sheet grinding wheels and ore-cutting grinding wheels.

Resin bonds can also be made into high-thickness grinding wheels, which are used for guide wheels for centerless grinding and simple grinding wheels for spindle surface grinders.

Resin bond has good polishing properties. The fine-grained grinding wheel made of it can be used for mirror grinding, and the surface roughness of the processed workpiece can reach Ra 0.012μm.

The manufacturing process of resin-bonded grinding wheels is relatively flexible. Glass fiber mesh can be added to increase the strength of the grinding wheel. It can be made into high-speed grinding discs and high-speed cutting discs with a speed of 60~80m/s, which can be used for welding or cutting.

This type of binder can also be combined with graphite materials or copper powder to create conductive grinding wheels, which achieve excellent results in electrochemical grinding.

③Rubber binders(R) are more elastic than resin binders and can be made into thin grinding wheels as thin as 0.2 mm or even thinner. These are used for cutting tasks such as spring clips and groove cutting for pen nibs. Rubber binders are prone to plastic deformation under high temperatures, and the surface roughness of the workpiece after grinding is relatively low, making them suitable for ultra-fine grinding or mirror finishing.

Rubber binder grinding wheels are also commonly used for grinding the inner and outer races of bearings. Flexible polishing wheels made from rubber binders can be used for processes such as polishing drill bit grooves, taps, dies, and aircraft engine blades.

The rubber bond grinding wheel has a greater friction force on the workpiece, and the guide wheels used on centerless grinders are almost all made of this bond.

The rubber bond grinding wheel has a relatively tight structure and is not suitable for rough grinding. However, it can better maintain the shape contour, so it can also be used to grind the formed surface.

④Magnesium binder (Mg) Grinding wheels made of this binder have poor bonding strength, but because it is easy to produce new sharp abrasive particles, the effect in some grinding processes is better than other binders. This binder is easy to hydrolyze and is generally not suitable for working under wet grinding conditions, so its application range is not wide. It is generally used to grind security blades, agricultural knives, paper cutting knives, grains, floors, and colloidal materials (such as toothpaste, and petroleum). When in use, the grinding wheel speed is generally within 20m/s.

⑤Other binders, such as metal binders, are commonly used in the production of diamond grinding tools.

In conclusion, the choice of binder in abrasive tools plays a crucial role in determining their performance, durability, and suitability for different grinding operations. Ceramic binders offer stability and high resistance under various conditions, making them ideal for precision grinding and forming applications. Resin binders, known for their elasticity and self-sharpening properties, are versatile for both rough and fine grinding, as well as cutting and polishing tasks. Rubber binders, with their flexibility, excel in ultra-fine grinding and mirror finishing, especially for delicate surfaces. Magnesia binders, though less widely used, can provide sharp cutting performance in specific grinding applications but are less suitable for wet grinding. Other binders, like metal binders, are essential for manufacturing diamond abrasives, offering strength and longevity for tough materials. Ultimately, selecting the appropriate binder depends on the specific grinding requirements, temperature conditions, and the desired surface finish of the workpiece.