Home / News & Blog / Abrasive Blog / Alumina and Silicon Carbide: Performance of Different Abrasives and Their Applications

There are many types of abrasives, and their selection principles are directly related to the physical and mechanical properties of the workpiece material being processed.

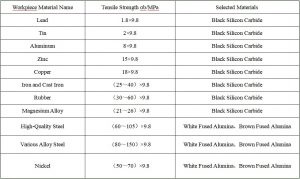

Generally, when grinding workpiece materials with high tensile strength, it is advisable to select tougher alumina-based abrasives. For workpiece materials with low tensile strength, it is preferable to choose silicon carbide abrasives, which are more brittle but have higher hardness. The tensile strength of some materials and the corresponding choice of abrasives are shown in Table 2-8.

Table 2-8 Selection of Abrasives

When selecting abrasives, it is important to consider the chemical reactivity between the workpiece material and the abrasive. The chemical reaction between the abrasive and the workpiece material is a primary cause of chemical wear on the abrasive. For example, severe chemical wear occurs when grinding steel with silicon carbide abrasives. In contrast, alumina-based abrasives do not exhibit this reaction during grinding, thereby avoiding chemical wear. Conversely, strong chemical reactions can occur when grinding glass with alumina-based abrasives, especially under water cooling. However, silicon carbide abrasives do not exhibit such reactions when grinding glass. Therefore, alumina-based abrasives are suitable for grinding steel workpieces but not for grinding glass, while silicon carbide abrasives are unsuitable for grinding steel.

The chemical affinity between abrasive and workpiece materials should also be taken seriously, especially the affinity between some difficult-to-process materials and abrasives is very obvious. For example, when silicon carbide abrasive is used to grind heat-resistant alloys because silicon carbide can react with iron by itself and under the high temperature in the grinding zone, silicon carbide can decompose and form compounds with certain metal components in the workpiece material (such as Co, Ni, Cr, W, etc.), causing the silicon carbide grinding wheel to wear more seriously. When single crystal corundum is used to grind heat-resistant alloys, better grinding results can be achieved. In addition, the red hardness of the abrasive should also be considered when selecting abrasives.

The following introduces the properties and applicable ranges of various abrasives.

①Brown Fused Alumina (A) abrasive has high toughness, high hardness, and sharp particles. Therefore, it is suitable for grinding materials with high tensile strength, such as carbon steel, ordinary alloy steel, malleable cast iron, hard bronze, etc. Brown Fused Alumina is cheap and widely used, and is regarded as a general abrasive. The second grade of brown fused alumina can be used as an abrasive for grinding wheels, sand tiles, sandpaper, sandpaper, and resin cutting wheels.

②White Fused Alumina (WA) abrasive has a slightly higher hardness than brown fused alumina but is less tough. Harder abrasives can penetrate the workpiece more easily, reducing workpiece deformation and grinding heat. White fused alumina abrasives are most suitable for fine grinding, tool sharpening, thread grinding, and grinding workpieces that are prone to deformation or burning. However, its price is higher than that of brown fused alumina.

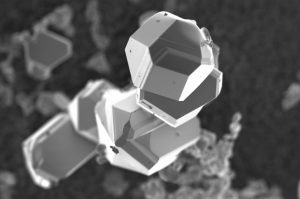

③Single crystal alumina (SA) abrasive has excellent multi-edged cutting edges, along with high hardness and toughness. This abrasive is not easily broken during grinding, offers strong cutting ability, and has a long service life. It is suitable for processing harder metals, such as high-vanadium high-speed steel, heat-resistant alloy steels, cobalt-based, nickel-based alloys, and stainless steels. Particularly, high-vanadium steel containing 2%–3% vanadium, which has poor grind ability and is difficult to grind with conventional abrasives, can be effectively processed using single-crystal alumina. When grinding quenched steel, tool steels, and other alloy steels, single crystal alumina abrasive delivers excellent grinding results. However, due to its relatively small production volume, it is primarily recommended for grinding heat-resistant alloys and hard-to-grind metal materials.

④Microcrystalline alumina (MA) has an appearance, color, and chemical composition similar to brown fused alumina, but its particles are composed of numerous tiny crystals. It features high strength, great toughness, and good self-sharpening properties, making it less prone to large particles breaking off during grinding. Abrasive tools made from MA exhibit minimal wear and are suitable for grinding materials such as stainless steel, carbon steel, bearing steel, and special ductile cast iron. It is also used for heavy-duty grinding and precision grinding.

⑤Chromium alumina (PA) abrasive has a hardness similar to white fused alumina but slightly higher toughness. It offers good cutting performance, high strength, and sufficient brittleness, making it less likely to cause burning or cracks on the workpiece surface during grinding. This also helps improve productivity. Abrasive tools made from PA have good retention properties, making them suitable for form grinding. Chromium alumina has better grinding performance than white fused alumina and can reduce surface roughness on the workpiece. PA is widely used for grinding hardened steel, alloy steel tools, thread grinding, as well as precision grinding of gauges and instrument parts.

⑥Zirconia alumina (ZA) is a composite oxide of Al2O3 and ZrO2, known for its good toughness. It is suitable for heavy-duty grinding, as well as grinding of heat-resistant alloys, titanium alloys, and austenitic stainless steels.

⑦Black fused alumina (BA) abrasive has a black appearance and exhibits a certain level of toughness. Its hardness is lower than that of brown fused alumina. It is commonly used for free grinding applications, such as pre-plating, polishing, or rough grinding. BA is also used in sandblasting and for making coarse grinding wheels, sandcloth, sandpaper, and similar products.

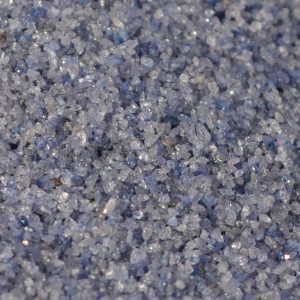

⑧Black silicon carbide (C) has a higher hardness than alumina-based abrasives, with sharp cutting edges, but it is brittle. It has good thermal conductivity, fast heat dissipation, and better self-sharpening properties compared to alumina abrasives. It is suitable for processing materials with low tensile strength, such as gray cast iron, white cast iron, bronze, brass, ores, refractory materials, aggregates, glass, ceramics, leather, rubber, and more. It is also ideal for grinding heat-sensitive materials and can be used for dry grinding. Black silicon carbide abrasives are widely used for free grinding and are commonly applied in cutting and shaping operations for jewelry, jade, agate, and other similar products.

![]()

⑨Green silicon carbide (GC) abrasives are harder and more brittle than black silicon carbide, with sharper cutting edges and fine-cut micro-blades that easily penetrate the workpiece. However, they are not as tough. In addition to having the same applications as black silicon carbide, green silicon carbide is particularly suitable for grinding hard carbide tools and workpieces, thread grinding, and fine grinding of such tools. It is also used for cutting and free grinding of materials such as agate, watch jewels, bearings, high-end jewelry and jade, and precious metals like germanium. Green silicon carbide is more expensive than black silicon carbide and should generally be used only for grinding carbide materials and high-precision workpieces, while black silicon carbide is preferred for other applications.

⑩Cubic silicon carbide (SC) is brittle yet sharp. Abrasives made from SC, such as oilstones and small grinding wheels, have strong grinding capabilities when used for ultra-fine grinding and channel grinding of miniature bearings. They are also effective in reducing the surface roughness of miniature bearings.

⑪Boron carbide (BC) abrasive is black, and its particles are more prone to fracture than diamond, forming new sharp cutting edges. It has good cutting performance retention. However, due to the relatively small scale of industrial production, boron carbide abrasives are typically available only in grain sizes of 100# and finer. Additionally, boron carbide has poor thermal stability and cannot withstand high temperatures. As a result, it is often made into a polishing paste or mixed with oils for free grinding. It is suitable for processing and polishing hard metals, gemstones, ceramics, molds, and precision components.

In conclusion, the various types of abrasives discussed, including white fused alumina, single crystal alumina, microcrystalline alumina, chromium alumina, zirconia alumina, black fused alumina, black silicon carbide, green silicon carbide, cubic silicon carbide, and boron carbide, each offer unique properties that make them suitable for specific grinding and polishing applications. The choice of abrasive material depends on factors such as hardness, toughness, thermal stability, and the specific characteristics of the material being processed. Harder abrasives, like white fused alumina and green silicon carbide, are ideal for fine grinding and precision work, while tougher abrasives like zirconia alumina and chromium alumina are better suited for heavy-duty grinding. Boron carbide, despite its limitations in thermal stability and grain size, excels in polishing and fine-grinding tasks. Understanding the strengths and limitations of each abrasive type ensures that the appropriate material is selected for efficient and high-quality processing across industries like metalworking, ceramics, jewelry, and precision engineering.