Home / News & Blog / Abrasive Blog / Binders, Abrasive Distribution and Causes of Failure of Coated Abrasives

Adhesive: This is divided into primer and compound adhesive. The primer is the adhesive between the abrasive and the backing, fixing the abrasive on the backing; the compound adhesive is applied on top of the abrasive and the primer to further fix the abrasive.

Common adhesives are:

PF resin glue: it is made from phenol formaldehyde, more solid

UF resin glue: it is made from urea formaldehyde, and the texture is relatively soft, toughness animal glue: has better flexibility and toughness

|

Adhesive |

Properties |

Use |

|

Resin Glue/Resin Glue |

Heat-Resistant Durable High Roughness Value |

Strong Cutting Long-Lasting High-Pressure |

|

Resin Glue/Animal Glue |

Hard Soft |

Flexible Material Removal |

|

Animal Glue/Animal Glue |

Soft Heat-Sensitive |

Polishing Handmade |

Abrasive Distribution State: It describes the distribution density of the abrasive on the backing of the coated abrasive, and usually has three forms:

1. OPK: open sand planting, with 30%-60% mineral sand adherence

2. SOPK: semi-open sand planting, with 70%-90% mineral sand attachment

3. CLK: dense sand planting, with 100% mineral sand adherence

Dense grit is suitable for strong cutting, high-pressure operation, and harder materials, the workpiece material is not easy to clog, and can achieve a better finish; open grit is suitable for unit pressure grinding with lower and progressively higher cutting volume, and at the same time, it can make the abrasive material break up progressively to minimize clogging, and it has better self-sharpening; open grit produces higher roughness values when the pressure is changed.

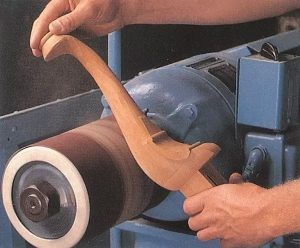

(Application of soft cloth-based abrasive belts)

Reasons for abrasive failure of coated abrasives and abrasive selection

The forms of abrasive failure and the causes that lead to them include the following three main categories:

1. Dullness of abrasives: Dullness is caused by the fact that the abrasives cannot be broken properly. Slippage caused by abnormal dullness stops the abrasive from grinding and generates frictional heat. The following reasons mainly cause operation without grinding and excessive pressure consumption:

Abrasive too hard or too fine a grain size

Too light a grinding pressure

Too much kneading

Unsuitable contact wheels

Excessive speed of the abrasive belt

2. Abrasive clogging: Clogging occurs between the abrasive voids when the grinding material is not removed in time causing clogging of the abrasive. This phenomenon is usually caused by workpiece materials with low hardness and large fragments, e.g. aluminum, rubber, and soft materials. Possible factors include:

Excessive pressure

Improperly fitted contact wheels

Excessive belt speed

Insufficient coolant

Insufficient dust extraction

3. Abrasive shedding: Abrasive shedding is the shedding of abrasive from the backing base when it is not completely worn out. It tends to occur when the pressure is too high and the load resistance is poor. Possible factors:

Abrasive too soft

Excessive material toughness

Excessive material depth of cut

Unsuitable contact wheel

Only localized involvement of the abrasive belt in the grinding

As for the choice of abrasive, when the workpiece material is different, the abrasive choice of the coated product is also different:

(The following are just the most common abrasive choices)

|

Material |

Coarse Grinding |

Polishing |

|

Aluminum (refined) |

AlO |

AlO |

|

Cast Aluminum/Forged Aluminum |

Nz/AlO |

AlO |

|

Copper and Bronze Castings |

Nz/AlO |

AlO/SiC |

|

Cast Iron-Softer |

Nz/AlO |

SiC |

|

Cast Iron – Harder, Nickel-Chromium Cold-Worked Castings |

Nz/AlO |

SG |

|

Forgings, Chromium-Vanadium Steel |

Nz |

AlO/SG |

|

Stainless Steel Castings, Investment Castings |

Nz |

SG/SiC |

|

Metal Structures, Welds, Thinner Workpieces |

Nz |

AlO/SiC |

|

Copper Alloy |

AlO |

AlO/SiC |

|

Plexiglas |

SiC |

SiC |

|

Density Board/Particle Board |

Nz/SiC |

SiC/SG |

|

Plywood |

AlO |

AlO |

|

Wood Raw Materials and Harder Wood |

Nz |

SG/AlO |

|

Furniture |

AlO |

AlO/SiC |

|

Glass Edge Bevel Grinding |

SiC |

AlO |

|

Granite Polishing |

SiC |

SiC |

|

Inconel |

Nz/TG |

SG/AlO |

|

Polished Leather and Suede |

SiC/AlO white |

AlO white |

|

Plastic and Fiberglass Materials |

SiC |

SiC |

|

Titanium Alloy |

Nz/SiC |

SiC |

|

Zinc Alloy |

SiC |

SiC |

(R889+ abrasive belt application)

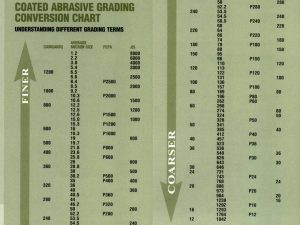

Let us now understand the abrasive particle size and standards:

(FEPA is the European standard; JIS is the Japanese standard)

Factors Influencing the Abrasive Performance of Coated Abrasives Include:

1. Abrasive Shape:

The height-to-width ratio of the abrasive grains in coated abrasives is L/D=3. The abrasive grains should have a certain sharp angular shape, and this shape must also be capable of resisting bending forces.

2. Hardness:

Hardness determines whether the abrasive has good grinding performance. If the hardness of the abrasive is insufficient, it will merely rub against the workpiece during grinding without penetrating it, resulting in poor grinding efficiency and rapid wear. The standard for selecting abrasives is that they must be suitable for grinding while possessing good self-sharpening properties.

|

Abrasive Hardness Classification |

|

|

Abrasive |

Grade |

|

Silicon Carbide |

1 |

|

Alumina |

2 |

|

Zirconia Corundum |

3 |

|

Carborundum |

4 |

|

Garnet |

5 |

|

Flint |

5 |

|

Grinding Powder |

5 |

(Hardness From High To Low)

(NorZon-Zirconia Corundum Abrasive)

3. Toughness:

Compared to aluminum oxide, silicon carbide has lower toughness, with NorZon being slightly less tough than aluminum oxide, and SG being less tough than NorZon. Aluminum oxide can improve its toughness through heat treatment, while white aluminum oxide is more brittle compared to brown aluminum oxide.

4. Self-Sharpening:

When the abrasive becomes dull, the grinding force and heat increase. Abrasive grains fracture, generating new sharp edges, a process known as self-sharpening during grinding. In manual operations, this property eliminates the need for the operator to apply additional excessive loads.

(Golf ball head polished with a pyramid sanding belt)

Based on the above knowledge, several common abrasive indicators are as follows:

|

Abrasive Index |

|||||

|

Abrasive |

Brown Alumina |

White Alumina |

Norzon |

Silicon Carbide |

SG |

|

Shape |

Block |

Block |

Sharp |

Rule |

Round Corners |

|

Hardness |

3 |

3 |

3 |

1 |

2 |

|

Self-Sharpening |

4 |

2 |

5 |

1 |

3 |

|

Toughness |

1 |

4 |

2 |

5 |

3 |

In addition, combined with the above knowledge points, the properties of common abrasives are summarized for your reference:

|

Synthetic Abrasives |

||

|

Abrasive |

Properties |

Use |

|

Alumina |

Hard, Blocky, Multi-Purpose |

Iron, Non-ferrous Metals, Wood |

|

Silicon Carbide |

Hard, Sharp, Poor Toughness |

Glass, Leather, Wood-based Panels, Polished |

|

Norzon |

Sharp, Fragile, Long Life |

Stainless Steel, Rough Ground, Metal Frame |

|

SG |

Particle Crushing, Sharp |

Productivity Increase, Size Determination |

(Sand disc paint polishing)