Home / Products / Brown Fused Alumina / Brown Fused Alumina For Sand Blasting

Brown fused alumina abrasive can also be widely used in sandblasting applications. Made from high-grade bauxite, iron filings and anthracite smelted at high temperatures in an electric arc furnace, it has excellent hardness and durability, making it ideal for surface preparation and cleaning.

Brown fused alumina abrasive has a Mohs hardness of 9 and can remove rust, scale and coating without damaging the underlying surface; it has an effective abrasive action, supports multiple repeated uses, and is resistant to high temperatures and corrosion

Surface treatment: Clean metal surfaces before painting or coating to ensure strong adhesion.

Rust and scale removal: Remove corrosion, scale and old paint layers on steel, iron and other materials.

Matte treatment: Create a uniform matte texture on glass, ceramics and metals.

Precision sandblasting: Clean precision parts or molds where minimal substrate damage is critical.

Brown aluminum oxide has a variety of particle sizes, such as F16–F120, to meet different sandblasting needs. Coarse sand is used for strong material removal, and fine sand can achieve a smooth surface.

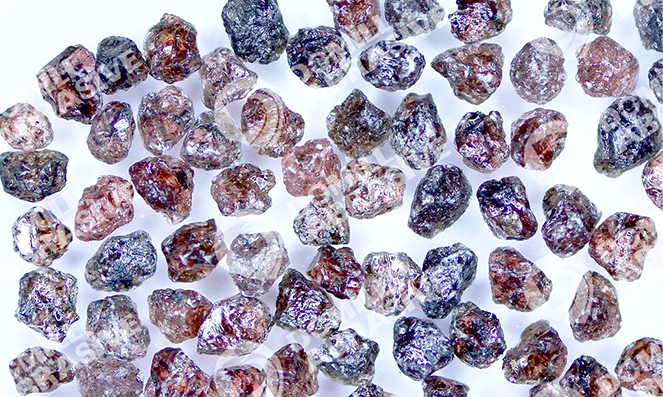

For example, DOMILL's A38 grains are blocky, high bulk density, good chemical stability, high hardness, high toughness, low magnetic properties, high cleanliness, particle shape closely sized, suitable for blasting of glass, marble, granite, ceramic and so on. It can also used for the preparation of deburring, scale removal, and the generation of matte finishes.

A38 is widely used in the industrial applications of ship repair, industrial painting, blast room, etc.

GRITS AVAILABLE:F4-F220

Customized sizes available upon request please refer to the TDS document below.

Please fill out the form.We will reply you in 24 hours.