Home / Products / Brown Fused Alumina / Coated Brown Fused Alumina For Coated Abrasives

Coated Brown Fused Alumina is a premium abrasive material designed specifically for the production of coated abrasives, such as sandpaper, sanding belts, and flap discs. The coating process enhances the grain's performance by improving toughness, reducing dust generation, and optimizing adherence to the abrasive backing.

Coated brown fused alumina refers to an improved grain that uses a certain amount of ceramic material plus special additives to wrap to the particle surface without gaps and calcine in a specific temperature and time. The irregularity surface bonds more intimately with phenolic resins. This gives longer abrasive belt life and improves grinding performance.

Sanding belts: P60-P120 grit for heavy-duty and fine-finishing tasks.

Flap discs and flap wheels: P40-P120 grit for metal polishing and surface preparation.

High-grade sandpaper: P50-P150 grit for woodworking, automotive refinishing, and other precise applications.

Non-woven abrasives: Nylon and sponge abrasives for surface finishing.

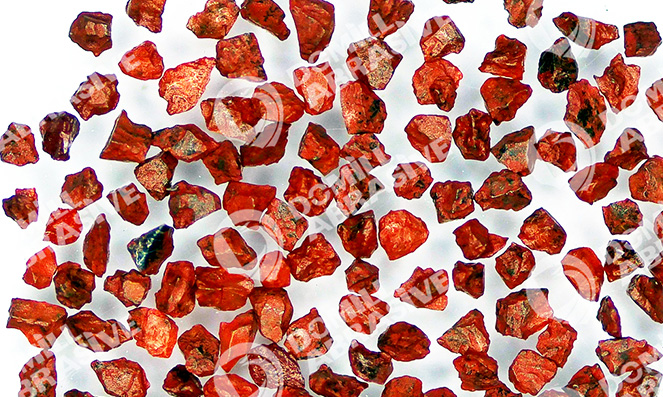

ATR25 is base on A25, angular, after coating and 1050 calcined, the color is light red, hydrophilicity is obviously improved. It has strong cohesive force, mainly used for top-grade coated abrasives, such as sandpaper, abrasive cloth, abrasive belt, for plank polishing, machining of low carbon steel, alloy steel.

ABR25 is base on AT25, after coating and 1350 calcined , the color is dark red, various indicators is better than ATR25. It is mainly used for manufacturing high-grade coated abrasives, for high-demand hardwood polishing and metal heavy-load abrasive belt grinding.

GRITS AVAILABLE:P12-P800

Customized sizes available upon request please refer to the TDS document below.

Please fill out the form.We will reply you in 24 hours.