Home / News & Blog / Abrasive Blog / From Coarse to Ultra-Fine: Understanding Sandpaper Grits for Perfect Finishes

Paper-based abrasives are relatively cheap and require no or only simple substrate treatment. Coated abrasives with paper-based backing are relatively flat and have unique adhesion, elasticity, weight, moisture absorption, and waterproof capabilities. Paper-based coated abrasives are light, easy to cut, and inexpensive. They are suitable for applications with low pressure and need to be attached to the surface of the workpiece when applied. Paper-based sandpaper is widely used in the processing of various materials such as metal, wood, plastic, and coated surfaces.

The weight of paper is represented by the letters A to F, with A being the lightest, weighing less than 80 g/m2, similar to the paper used for printing; and F being the heaviest, weighing between 250-320 g/m2, similar to the paper used for laminated covers of company brochures. Lightweight paper can only be used for sheet sandpaper or disc sandpaper, while heavier paper is required for sand belts. Wide-width sand belts can only be made with F-type paper.

|

Weight |

g/m2 |

Characteristics |

Applications |

|

A |

below 80 g/m2 |

flexible |

hand |

|

B |

80-150 g/m2 |

flexible |

hand |

|

C |

105-125 g/m2 |

flexible/durable |

hand/orbital sander |

|

D |

125-160 g/m2 |

flexible/durable |

hand/orbital sander |

|

E |

220-250 g/m2 |

more durable |

abrasive belt |

|

F |

250-320 g/m2 |

more durable |

wide, narrow abrasive belt |

1. Sandpaper Sand Roll

Sandpaper rolls refer to sandpaper made of paper as the base material and then cut into sheets or rolls of various sizes. The most common sheet sandpaper is A4 paper size (230*280mm) sheet sandpaper, which is convenient for manual use; rolls are small sandpaper rolls of different widths and lengths, which are cut into various sizes and shapes according to needs.

The page-shaped design or cutting into a shape that the user can hold directly in the hand is suitable for grinding curved surfaces, corners, and small workpieces. It is mainly divided into dry sandpaper and water sandpaper.

Dry sandpaper: designed for manual sanding in dry environments, usually used to remove burrs and smooth surfaces on wood and metal surfaces.

Wet sandpaper(also known as water sandpaper): It is highly water-resistant and can be used for wet sanding. It is commonly used in automotive painting, plastics, and other scenes where dust reduction is required.

The grit range of sheet sandpaper is very wide, mainly classified from coarse to fine according to the application requirements. Common grit specifications are as follows:

Coarse grit: P40-P80. This type of sandpaper has larger abrasive particles and is suitable for coarse grinding. It is used to quickly remove a large amount of material from the surface of the material. For example, removing paint layers, removing rust, or smoothing rough surfaces.

Medium grit: P100-P220. This type of sandpaper is suitable for moderate grinding and smoothing, used for preliminary surface finishing of materials. For example, it is used to remove rough areas and even out surface textures during wood sanding.

Fine grit: P240-P400, suitable for fine grinding and surface smoothing. It is commonly used for metal polishing, paint surface treatment, and similar applications.

Ultra-fine grit: P600 and above, ultra-fine sandpaper is used for very delicate sanding and polishing. For example, it is used in the final steps of automotive paint touch-ups and for fine polishing of plastic surfaces.

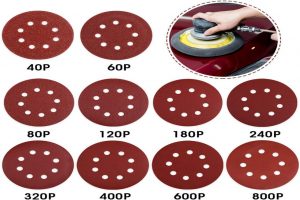

2. Disc Sandpaper

Disc sandpaper is a type of circular sandpaper that can be used with handheld electric sanders, pneumatic sanders, and other equipment. Its back can have different fastening methods, such as pressure-sensitive adhesive (PSA) or hook-and-loop (also known as Velcro). The design allows for easy replacement during operation and is compatible with dust extraction systems on sanders. With hole designs (such as 6, 8, 9, 15, 17, 40 holes, etc.), it effectively removes sanding dust, making it suitable for large-area flat sanding tasks.

PSA disc sandpaper: The back is coated with Pressure Sensitive Adhesive (PSA), allowing for quick attachment and replacement. It is suitable for work environments where frequent sandpaper changes are required, such as in automotive repairs, woodworking, and sanding tasks.

Hook & Loop Disc Sandpaper: With Velcro on the back, it can be quickly installed and removed and has strong reusability. It is mainly used in woodworking, metal processing, and car polishing.

Common grit range of disc sandpaper

Coarse grain size: P24-P80. It’s suitable for coarse grinding and is mainly used to quickly remove a large amount of material on the surface of the material. For example, remove thick coatings, rust, burrs, and large areas of rough surface treatment.

Medium grit: P100-P220. It’s suitable for medium sanding tasks and preliminary surface smoothing. It can also remove thinner coatings and even out surface textures, such as wood, metal, and plastic refinishing.

Fine grit: P240-P600. It’s used for fine sanding and polishing to produce a smoother surface finish. It is suitable for preparation work before painting and detailed surface treatment, such as automotive sanding and furniture refinishing.

Ultra-fine grit: P800-P2000. These grits are mainly used for high-precision surface finishing and polishing, such as polishing automotive surfaces, mirror finishing metals and sanding plastic parts.

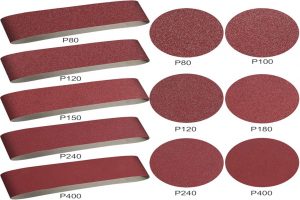

3. Heavy-Duty Sandpaper Belts

Heavy-duty sandpaper belts are sanding belt products made from thick, durable paper backing, using a higher weight of the base material to provide stronger support and durability. These sandpaper belts are suitable for processes that require high cutting force, such as metalworking, heavy wood stripping, weld seam cleaning, and sanding rough surfaces, as they can withstand higher pressure and grinding forces. They are less likely to tear or become damaged, have a long service life, and can support high-load operations. The grit range of heavy-duty sandpaper belts is quite broad, with options available for both coarse grinding and fine sanding. The commonly used grit sizes are as follows:

Coarse grit: P24-P80. These grits have larger abrasive particles and are suitable for coarse grinding, used for quickly removing large amounts of material, sanding uneven surfaces, and performing initial processing. Examples include eliminating weld seams, rust removal, and sanding rough wood surfaces.

Medium grit: P100-P220. Medium-grit belts are used for moderate sanding tasks, ideal for further surface leveling, removing medium-thickness paint layers, or deburring. This grit range effectively removes material while providing a relatively smooth surface finish.

Fine grit: P240-P600. Fine-grit belts are used for precise sanding and polishing, making them suitable for detailed surface finishing. They are commonly used for sanding metal surfaces, pre-paint sanding of wooden furniture, and fine polishing before automotive painting.

Ultra-fine grit: P800 and above. These ultra-fine grit belts are designed for precision polishing, providing an exceptionally smooth surface finish. They are commonly used for high-precision surface treatments, such as automotive polishing, metal mirror finishing, and fine sanding of plastic surfaces.

In conclusion, sandpaper is a versatile and essential tool for a wide range of surface finishing applications across industries such as woodworking, metalworking, and automotive refinishing. With various forms like sheet sandpaper, disc sandpaper, and heavy-duty sandpaper belts, each designed for specific tasks and environments, selecting the right type and grit size is crucial for achieving optimal results. From coarse grits for rapid material removal to ultra-fine grits for precision polishing, sandpaper plays a vital role in surface preparation and finishing. Understanding the unique properties of each type ensures efficient, high-quality results, making it a critical component in any sanding or finishing project.