Home / News & Blog / Abrasive Blog / How to Maximize the Cost-Effectiveness of Brown Fused Alumina in Bulk Production

Brown Fused Alumina (BFA) is a critical material in many industries, including metalworking, abrasives manufacturing, and refractories. For manufacturers focused on bulk production, optimizing the cost-effectiveness of BFA is crucial. By using the right strategies in sourcing, production, and quality control, manufacturers can achieve high performance while keeping costs low.

In this blog, we will explore how bulk producers can maximize the value of their BFA supply, from selecting the right grades to implementing effective quality controls.

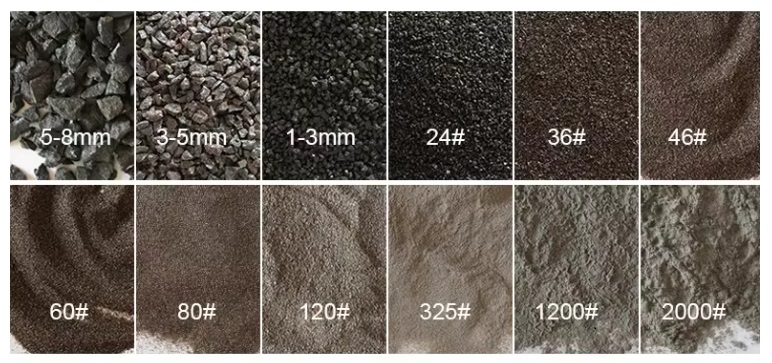

The first step in maximizing cost-effectiveness is selecting the correct grade of BFA for your application. There are different types of BFA, and each has distinct characteristics, including hardness, toughness, and friability. Understanding which type best suits your application can reduce waste and increase productivity. Here are some considerations for selecting the right grade:

Standard BFA: Ideal for general-purpose use in grinding wheels, abrasive tools, and cutting materials.

High-Purity BFA: Typically used in precision grinding and high-performance applications that require consistency and low impurity levels.

Semi-Friable BFA: Best suited for applications where moderate durability and increased cutting efficiency are needed.

Choosing the right grade will prevent unnecessary costs caused by over-specification and help maintain the balance between quality and cost.

Once the right grade has been identified, sourcing becomes the next important factor in controlling costs. When buying BFA in bulk, it’s essential to secure competitive pricing from reliable suppliers. Here’s how to approach sourcing:

Bulk Discounts: Purchase large volumes of BFA to take advantage of bulk discount rates from suppliers. This is a key way to lower per-unit costs in long-term contracts.

Reliable Suppliers with Quality Assurance: While lower cost is important, working with suppliers who offer consistent quality and reliable delivery is essential to prevent production delays and ensure a steady supply chain.

International Sourcing: Look at sourcing opportunities from global markets, where BFA production may offer competitive pricing without compromising quality. This also ensures a diverse supply chain.

Negotiating the best deals with your supplier based on your volume requirements and establishing long-term relationships can lead to significant savings in the long run.

The efficiency of your manufacturing process plays a major role in controlling costs. Inefficient production methods can lead to high material waste, which increases costs. Here are some ways to reduce waste and improve efficiency:

Optimized Equipment: Ensure your production lines are using the most up-to-date equipment that maximizes output while reducing material loss. Regular equipment maintenance and calibration are also important for maintaining efficiency.

Automated Quality Control: Implementing automated quality control systems can help identify any defects in BFA before it reaches production lines. This ensures that only the most consistent and highest-quality material is used, preventing the need for rework and reducing scrap material.

Process Monitoring: Utilize real-time data monitoring systems to track the usage of BFA during production. This helps identify areas where improvements can be made, such as reducing wastage in cutting or grinding operations.

By investing in technology and fine-tuning production processes, manufacturers can significantly cut down on waste, improving their cost-effectiveness.

Quality control is essential when dealing with bulk quantities of abrasive grains. Even minor inconsistencies in BFA quality can lead to significant performance issues, downtime, and waste. Implementing stringent quality control measures will ensure that the BFA used in production is of consistent quality throughout the batch.

Batch Testing: Regular testing of BFA batches for purity, particle size distribution (PSD), and hardness ensures that only high-quality material is used in production.

Supplier Audits: Conducting supplier audits to assess their production standards and quality assurance practices can help ensure that the BFA you’re purchasing consistently meets your requirements.

Standard Operating Procedures (SOPs): Develop and follow SOPs for inspecting, testing, and handling BFA materials. This guarantees that no defective or inconsistent material is used in production.

By maintaining a high standard of quality control, manufacturers can avoid costly rework and product failure, ensuring that BFA performs as expected across all production runs.

Another strategy for improving cost-effectiveness is recycling and reusing BFA. This is especially beneficial for industries where large quantities of abrasive grains are used regularly, such as metalworking and sandblasting.

Closed-loop Recycling: In industries such as metal cutting and sandblasting, BFA can be recycled and reused several times without significant degradation in performance.

Recycling Program Implementation: Set up an in-house recycling program that focuses on collecting used BFA for repurposing in future production. This will reduce material consumption and lower overall costs.

Incorporating recycling programs can further reduce the overall material costs and contribute to a more sustainable business model.

The key to maximizing the cost-effectiveness of Brown Fused Alumina in bulk production lies in understanding the balance between quality, sourcing, and efficient manufacturing processes. By selecting the right grades, negotiating competitive prices, optimizing production efficiency, ensuring batch-to-batch consistency, and incorporating recycling, manufacturers can significantly reduce costs without compromising on performance.

At DOMILL ABRASIVE, we specialize in providing high-quality BFA that meets the demands of industrial manufacturers worldwide. Whether you’re producing grinding wheels, refractories, or sandblasting materials, our BFA can help your business achieve better results at a competitive price.

Let’s discuss how we can help optimize your abrasive grain sourcing strategy and enhance your production efficiency.