Home / News & Blog / Abrasive Blog / Non-Woven Abrasive Tools: Enhancing Surface Treatment Efficiency

Non-woven abrasive tools are an important innovation in surface treatment, offering a better option than traditional sandpaper and abrasive belts. Made from synthetic fibers and abrasive grains, these tools are highly flexible, elastic, and adaptable to different surfaces. They are commonly used for cleaning, polishing, deburring, and finishing in metalworking, automotive, aerospace, and furniture manufacturing industries. We explore two main types of non-woven abrasives—industrial scouring pads and nylon abrasives—and explain their structure, uses, and benefits for achieving excellent surface results.

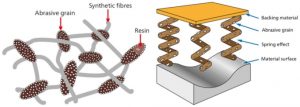

Non-woven fabrics are cloth-like materials that are made of natural or artificial fibers fixed into a fiber mesh. They are light, elastic, soft, acid-resistant, alkali-resistant, and tear-resistant. As shown in Figure 5.2: Basic structure of non-woven abrasive tools

Abrasive tools with an open mesh structure made of non-woven fabrics (synthetic fibers) bonded with abrasive grains (resin) are called non-woven abrasive tools or non-woven abrasive tools. Compared with traditional sandpaper and abrasive belts, non-woven abrasives have better elasticity (Spring effect) and flexibility during grinding due to their unique structure. They can effectively adapt to various complex surfaces (Material surface). They are widely used in cleaning, polishing, deburring, and surface treatment. Non-woven abrasives are mainly divided into industrial scouring pads and nylon abrasives.

1. Industrial scouring pad

Industrial scouring pads are a type of tool specifically used for light cleaning and surface polishing. They are made of wear-resistant synthetic fibers, resins, and abrasive particles. By evenly distributing the abrasive in a three-dimensional fiber network, the abrasive can effectively remove dirt and oxide layers while avoiding surface damage when processing the surface. Due to its structural design, the scouring pad has good flexibility and self-sharpening properties, can adapt to various complex surfaces, and is particularly suitable for operations on irregular shapes and details.

Industrial scouring pads are widely used in metal processing, automobile manufacturing, aerospace, furniture manufacturing, electronic equipment maintenance, and other fields. They are often used to remove rust, oxide layers, welding marks, and oil stains, as well as polishing and fine surface treatment.

The large rolls of industrial scouring pads produced can be cut into rolls of different widths and lengths for sale. Users can cut them again according to their needs, or the manufacturer can directly cut them into sheets for users to use directly. They are often used for manual cleaning and polishing, suitable for removing dirt, oil, and surface oxide layers. Industrial scouring pad rolls can also be converted into discs or wheels and installed on power tools for surface treatment and fine polishing.

The particle size of industrial scouring pads is mainly determined by the size of the abrasive particles. Common particle sizes range from coarse to ultra-fine. The following are the common particle size classifications of industrial scouring pads:

Coarse: Abrasive with large particles, suitable for removing thick rust, paint, dirt, etc. This type of scouring pad has larger particles and a stronger grinding effect. Common particle sizes are P60 and P80.

Medium: Suitable for removing light rust and surface dirt and for most general cleaning and sanding tasks. Common grit sizes are P100 – P180.

Fine: Fine-grain abrasive, suitable for surface smoothing, light sanding, and removing fine scratches. Common grit sizes are P240 – P400.

Ultra–Fine: Ultra-fine particles are mainly used for precision polishing and final surface finishing, with common grit sizes of P600 and above.

International and domestic manufacturers usually color-code industrial scouring pads according to different particle sizes and grinding forces. Different colors represent different abrasive particle sizes and grinding performance. However, the colors on the market are quite confusing, and each manufacturer has its color system. The following is for reference only:

Brown, Gray: usually used for coarse grinding

Red, green: for medium sanding

Blue, white: for fine grinding and polishing

This color coding helps users quickly identify the type of scouring pad that is suitable for them so that they can do their job better.

2. Nylon abrasive tools

Nylon abrasives are a type of non-woven abrasives. They use nylon fibers as the base material and fix the abrasive in the nylon mesh structure through resin to form a soft, open three-dimensional abrasive.

This structure enables nylon abrasives to adapt to various complex surfaces, perform uniform grinding and polishing operations, and have a certain degree of elasticity and durability. Nylon abrasives are widely used in metal processing, automobile manufacturing, furniture manufacturing, aerospace, and plastic industries. Nylon abrasives perform well in tasks such as surface polishing, rust removal, oxide layer removal, and weld cleaning.

Although nylon abrasives include nylon coils, nylon abrasive discs, and nylon abrasive belts, the most common nylon abrasives are nylon polishing wheels (grinding wheels), which are disc or wheel-shaped nylon abrasives suitable for installation on polishing machines for deburring, surface polishing, and cleaning of materials such as metals and wood.

The nylon polishing wheel adopts the non-woven fabric process, which combines nylon fibers with a binder, adds abrasives, bonding resins, and other main materials, and then adds various additives such as heat-absorbing additives, fillers, colorants, etc. to form a flexible and elastic polishing wheel. Due to its three-dimensional open structure, nylon polishing wheels can provide uniform grinding effects and are not easy to clog during the grinding process. They are widely used in surface treatment of various materials, including metal surface cleaning, such as removing oxide layers, rust, stains, deburring, and surface polishing, and decorative surface treatment, such as providing matte, brushed, and other effects for metals or other materials.

The particle size of nylon polishing wheels is mainly determined by the usage scenario. From rapid grinding of rough surfaces to fine surface polishing, the application range of each particle size is different.

Coarse: P60-P80, mainly removes larger surface defects, oxide layers, heavy rust, welding marks, etc. Nylon polishing wheels with coarse grit have high cutting forces and can remove material quickly.

Medium: P100-P180, for general surface cleaning, removal of light rust, an oxide layer, small burrs, etc., suitable for preparatory grinding before subsequent finishing.

Fine: P240-P400, for processing finer burrs, minor scratches, and surface smoothing, usually used in processes that require a smoother surface.

Ultra–Fine: P600-P1000 and above are final surface treatment and high-precision polishing, used for workpieces with high requirements for surface finish, such as polishing of metal parts, removal of tiny scratches, and decorative polishing.

The color coding of nylon polishing wheels is similar to that of industrial scouring pads. The following is for reference only:

Brown, black: generally represents rough grinding or deburring

Red, green: for medium sanding

Blue, gray: for fine grinding and polishing

White: for ultra-fine polishing

Non-woven abrasive tools, such as industrial scouring pads and nylon abrasives, have transformed surface treatment across various industries. Their flexibility and wide range of uses make them essential for jobs like rust removal, cleaning, and precision polishing. By choosing the right type, grit size, and color-coded classification, users can achieve efficient and high-quality surface finishes. As industries focus on precision and efficiency, non-woven abrasives will continue to play a key role in surface treatment solutions.