Home / Applications / Organic Abrasives

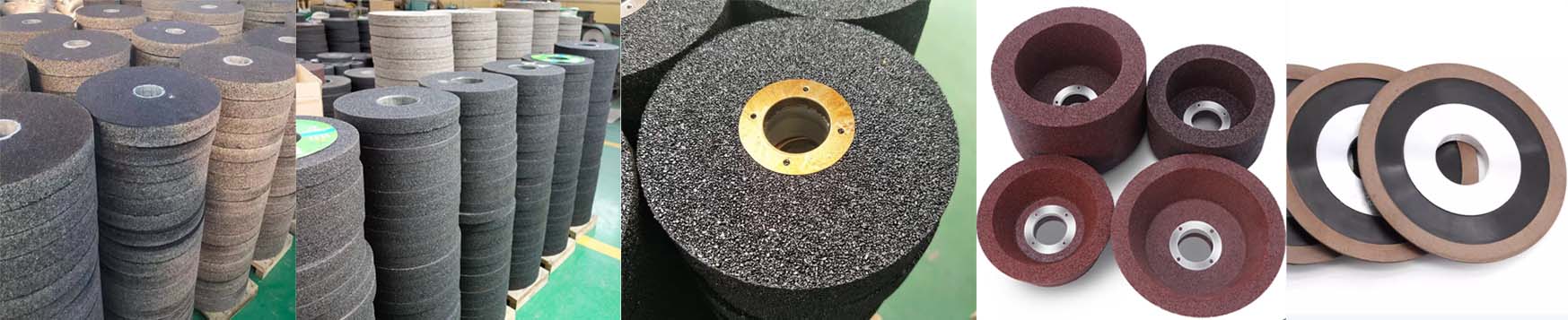

Organic abrasives are grinding tools made by bonding abrasive grains with an organic polymer binder, such as resin or rubber. These abrasives are typically used in the form of sandpaper, sanding belts, grinding wheels, and cutting discs. Compared to metal or ceramic abrasives, organic abrasives offer advantages like flexibility, lighter weight, higher toughness, and adaptability to various processing needs.

At DOMILL, we specialize in high-quality abrasive grains such as brown fused alumina, white fused alumina, and pink fused alumina, which are widely used in the production of organic abrasives. Our products ensure superior performance across different industries, including metalworking, automotive, wood processing, and more.

The typical products of thin wheels are resin bonded cutoffs and depressed center grinding wheels.

For the general hardware market, regular brown fused alumina and white fused alumina are basic raw materials to produce them.

For stainless steel cutting, if needs sharper, get the fast cutting effect, coated white fused alumina or monocrystalline alumina is a good choice.

For the grinding of carbon steel, if needs a better product life in higher grinding pressure condition, coated brown fused alumina or zirconia alumina 25 is a better choice.

The typical products of heavy duty wheels are large diameter cutting wheels and roll grinding wheels. monocrystalline alumina, 1350 calcined alumina or zirconia alumina 25 is a good choice.

The made rubber abrasive wheels are highly suited for the precision grinding, de-burring of high carbon steels, high temperature alloys. The made PVA & PU wheels are highly suited for polishing , AM10 is a better choice.