Home / News & Blog / Abrasive Blog / Pink Fused Alumina (PFA): The Material Of Choice for Industrial Grinding and High-Temperature

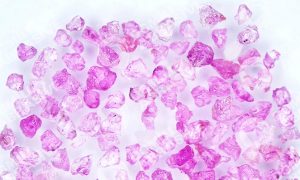

Pink Fused Alumina is a high-performance refractory material made from aluminum oxide (Al2O3) and chrome oxide (Cr2O3). Its color is light purple and pink, its hardness is similar to white fused alumina, its toughness is higher than white fused alumina and it has a very high chemical and thermal stability. It is widely used in industrial grinding and high-temperature environments due to its excellent resistance to high temperatures, abrasion, and corrosion and is the material of choice in many industries.

For precision grinding, the high hardness and good toughness of pink fused alumina make it an ideal abrasive. It can be used to manufacture a variety of abrasives, such as grinding wheels, sandpaper, and abrasives, which are widely used in metalworking, automotive manufacturing, aerospace, and other industries. Pink fused alumina abrasives are sharpened and have a low heat generation rate, which improves machining efficiency while reducing wear on the workpiece and ensuring the finish of the machined surface.

In addition to grinding applications, pink fused alumina is also favored in the high-temperature industry due to its excellent resistance to high temperatures. It is used in the manufacture of refractory bricks, furnace linings, and thermal insulation material for high-temperature environments such as cement kilns, glass furnaces, and steel smelting furnaces. Pink fused alumina’s high melting point and resistance to thermal shock enable it to maintain stable performance at extreme temperatures, thereby extending the life of the equipment and increasing productivity.

Pink fused alumina is chemically stable and highly resistant to acids and bases, which makes it to perform well in chemical and corrosive environments. Its resistance to wear and impact makes it widely used in construction, mining, and road engineering.

With the global emphasis on sustainable development, pink fused alumina, as a recyclable and reusable abrasive, meets the requirements of environmental protection and circular economy. Its use reduces the exploitation of natural resources and lowers energy consumption and waste emissions in the production process.

With the continuous progress of science and technology and the continuous expansion of application fields, the performance and application of pink fused alumina are also being upgraded and improved. The comprehensive performance of pink fused alumina can be further improved through compounding and modification treatment with other materials to meet more complex and demanding industrial requirements. Meanwhile, with the development of intelligent manufacturing and digital technology, the production and application of pink fused alumina will also be more intelligent and precise, bringing more innovation and breakthroughs in the field of industrial grinding and high temperatures.

Overall, pink fused alumina’s excellent hardness, abrasion resistance, high-temperature resistance, and environmental protection properties make it highly competitive and widely applicable in industrial grinding and high-temperature applications. In the future, as technology advances and applications continue to expand, pink fused alumina will continue to lead the development trend of industrial materials and contribute more to the prosperity and development of modern industry.