Home / News & Blog / Abrasive Blog / How Are Abrasive Grains Processed for Resin Grinding Wheels?

Ever wondered why some grinding wheels last longer and cut better than others? The secret lies in how the abrasive grains are processed before they even make it into the final product. If you’re in manufacturing, knowing how abrasives are made and treated can help you pick the best ones for your needs.

Let’s break it down in plain, simple terms so you can understand why processing matters.

Not all grinding wheels are the same. Different materials are used depending on what kind of grinding you’re doing. Here are some of the most common ones:

Brown Fused Alumina (BFA) – Tough and durable, great for grinding steel and general-purpose use.

White Fused Alumina (WFA) – Super sharp and pure, perfect for high-speed precision grinding.

Silicon Carbide (SiC) – Crazy hard and sharp, best for grinding glass, ceramics, and non-ferrous metals.

Single Crystal Fused Alumina – Strong and efficient, ideal for heavy-duty industrial grinding.

Using the wrong abrasive grains can lead to overheating, uneven grinding, and shorter tool life. Always match the abrasive to the job!

For resin abrasives, having super low magnetic content isn’t a big deal, but the surface quality of the abrasive grains really matters. That’s because graphite and dust sticking to the grains can weaken the bond between the resin and the abrasives, making the grinding tool less tough and durable. To boost the bonding strength and improve the overall toughness, durability, and wear resistance, abrasives need some extra processing. Common treatments include calcination (heat treatment), shaping the grains, applying surface coatings, and even slight surface etching.

Once the raw material is chosen, it’s crushed and shaped to get the right size and form. This step affects how sharp, tough, and durable the abrasive grain will be in a grinding wheel.

Different Crushing Methods:

Barmac Crushing – Produces sharp, blocky grains for aggressive cutting.

Ball Milling – Rounds out the grains, making them less aggressive but longer-lasting.

Shaping Machines – Refines grain shape so they cut better and wear more evenly.

Industry Secret: Shaped grains last longer because they bond better with the resin in the wheel.

Abrasives used in resin grinding wheels must have low magnetic content to prevent contamination during high-speed grinding. Magnetic matter in abrasives can lead to uneven wear, surface defects, and potential damage to precision workpieces.

Magnetic Separators – Remove ferrous impurities from the abrasive grains.

Multiple-Stage Processing – Ensures thorough removal of contaminants for ultra-pure abrasives.

That’s why magnetic separation is used to remove unwanted metal particles. The cleaner the grain, the more reliable and high-performing the grinding wheel will be. If you’re working with precision grinding, make sure the magnetic content is below 0.05%.

One of the most overlooked but critical steps in abrasive processing is thermal and surface treatment. These processes improve grain stability, resin adhesion, and overall grinding performance.

Calcination (Heat Treatment at 1050-1300°C) – Removes volatile impurities and enhances grain toughness.

Coating Treatment – Adds a layer of special compounds (such as TiO₂, Al₂O₃, or silane) to improve bonding with resin.

High-quality coated abrasives extend the lifespan of resin grinding wheels by 10-30% due to improved grain retention in the bond.

Resin abrasives require precise grain size distribution to ensure even wear and consistent cutting efficiency. This is controlled through advanced screening and air-classification processes.

Narrow Size Distribution – Produces consistent grinding behavior and predictable wheel wear.

Customized Grading – Some applications require specific grain distributions for optimized stock removal rates and surface finish.

Poor grain size control leads to inconsistent cutting performance and can cause premature wheel failure. Always source abrasives with strict grading quality control.

Moisture content in abrasives affects how well they bond with resin. High moisture content can cause resin degradation, leading to:

Weaker bonding strength

Reduced grinding wheel lifespan

Inconsistent performance

Best Practices for Moisture Control:

Final Drying Stage (100-200°C) – Ensures abrasives have the optimal moisture level before mixing with resin.

Sealed Packaging – Prevents moisture absorption during storage and transportation.

Ideal moisture content should be ≤0.1% to maintain optimal resin bonding strength.

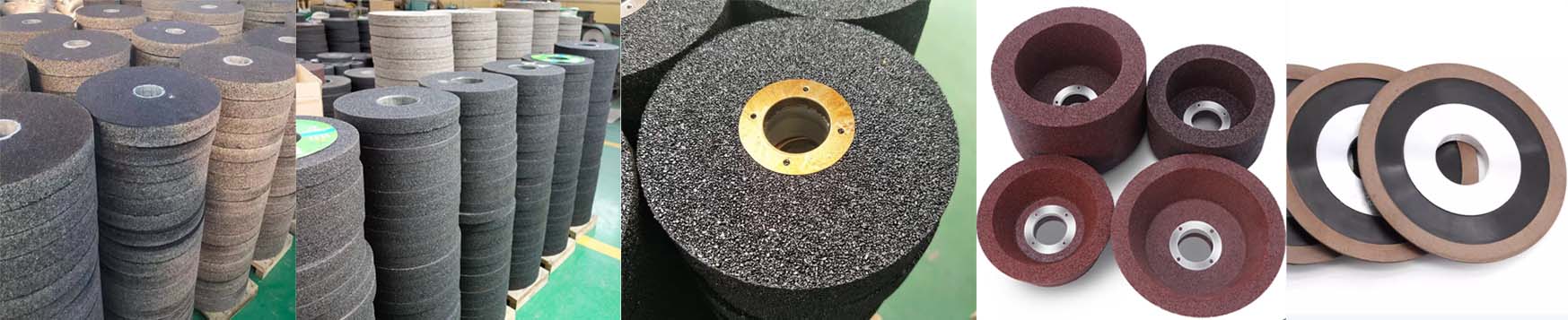

The performance of resin-bonded grinding wheels directly depends on the quality of the abrasive grains used. Proper processing techniques—such as shaping, calcination, coating, and precise grading—can significantly enhance cutting efficiency, tool life, and overall grinding consistency.

At DOMILL ABRASIVE TECHNOLOGY, we make sure every grain meets the highest standards for resin abrasives. Want to learn more? Visit www.domill.com and see how we can help optimize your grinding process!