Home / News & Blog / Abrasive Blog / The Development History of Abrasive Grains

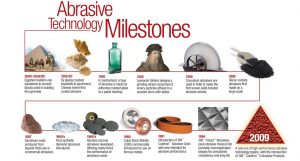

The development history of abrasive grains can be traced back several centuries, particularly in their application in machining and polishing technologies. The following are the key stages in the development of abrasive grains:

1. Early Stage:

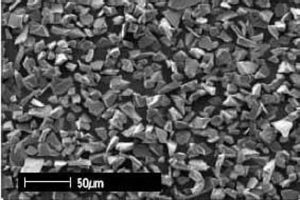

In the 19th century, abrasives were primarily used for rough machining operations. The abrasive grains, such as silicon carbide and aluminum oxide, were relatively large, with grain sizes typically ranging from 5 to 50 μm. These abrasives were suitable for removing significant amounts of material but were not ideal for achieving very high surface finishes.

2. Modern Development Stage:

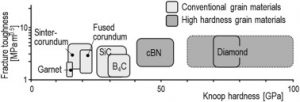

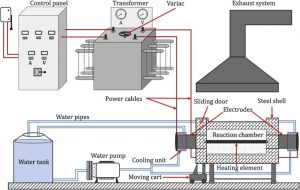

By the 19th century, industrial production increasingly demanded higher hardness and precise sizes for abrasive grains, leading to the adoption of synthetic abrasives. In 1893, American inventor Edward G. Acheson produced silicon carbide (SiC) using an electric resistance furnace, marking the advent of synthetic abrasive grains. By the mid-20th century, the emergence of superhard abrasives such as synthetic diamond and cubic boron nitride (CBN) further accelerated the advancement of modern abrasive processing technologies.

3. High-Tech Application Stage:

After 1985, with the development of the semiconductor industry, higher demands were placed on the purity and uniformity of abrasive grains. Finer abrasives, such as ultra-pure colloidal silica, were introduced during this period. These abrasives achieved unprecedented levels of size control and purity, meeting the requirements of Chemical Mechanical Planarization (CMP) technology in semiconductor chip manufacturing.

4. Standardization Efforts:

With the advent of industrialization, the need for standardized abrasive grains became evident. Organizations and associations in different countries began to develop grading systems to unify specifications. For instance, the FEPA (Federation of European Producers of Abrasives) and ANSI (American National Standards Institute) introduced grading standards that categorized abrasives by size and application. These standards ensured compatibility across tools and industries, enhancing efficiency and quality.

5. Modern Technology Application Stage:

In the 21st century, the development of abrasive grains has become increasingly reliant on high-tech preparation and analytical methods. For example, in semiconductor manufacturing, stringent quality control and advanced inspection technologies are employed to ensure that each batch of abrasives’ grain size meets the production process’s rigorous requirements.

Overall, the development history of abrasive grains aligns with the increasing demands for surface quality in industrial and high-tech fields. With advancements in technology, the control of abrasive grains has become increasingly precise to meet the needs of higher-precision processing.