Home / News & Blog / Abrasive Blog / What is the price of Brown Fused Alumina Abrasive?

The price of Brown Fused Alumina (BFA) abrasive varies depending on the region and product specifications. According to the latest market quotations in China:

BFA Blocks: USD 670–USD750 per ton

BFA Grains: USD 730–USD 850 per ton

These prices are based on ex-factory costs inclusive of tax and are subject to market fluctuations. Actual transaction prices may vary depending on specific agreements and conditions. For the most accurate pricing, you can contact your supplier or visit DOMILL Brown Fused Alumina Abrasive.

As a abrasives tool manufacturer and purchaser, you must also be interested in the following contents about brown corundum abrasive. We will discuss the factors influencing brown fused alumina price, provides insights into its HS code, and highlights the role of aluminum oxide manufacturers in its production.

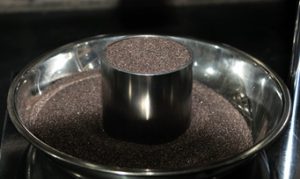

Brown Fused Alumina is a synthetic material produced by fusing high-quality bauxite and other raw materials in an electric arc furnace. It primarily consists of aluminum oxide (Al₂O₃) with small amounts of iron, titanium, and silica. The result is a tough, dense material suitable for abrasive and refractory applications.

Hardness: Excellent for grinding, cutting, and polishing.

Thermal Resistance: Withstands high temperatures in industrial processes.

Durability: Ensures longevity in abrasive tools.

Chemical Stability: Inert in most environments, making it versatile.

The price of brown fused alumina can vary significantly based on several factors:

1. Raw Material Costs

Bauxite is the primary raw material for BFA production. Variations in bauxite prices directly impact the cost of brown fused alumina. Factors such as mining restrictions and geopolitical issues can affect bauxite availability.

2. Production Process

The cost of electricity, which powers electric arc furnaces, is a major expense in BFA production. Efficient production methods can help manage costs, but fluctuations in energy prices often influence the overall price.

3. Purity and Grades

Higher grades of brown fused alumina, with fewer impurities and consistent grain size, command a premium price. Specialized processing, such as calcination or surface treatments, can also add to the cost.

4. Market Demand and Supply

Global demand for abrasives and refractories directly affects prices. Shortages in supply or increased industrial demand can drive prices upward.

5. Logistics and Transportation

Shipping costs, especially for international trade, play a role in pricing. The weight and bulk of BFA make transportation a significant expense.

In today’s market, fluctuations in raw material prices, stock shortages, and unstable freight costs are common challenges faced by buyers. Below are targeted recommendations to help you maintain competitiveness amid uncertainty:

1.Establish Long-Term and Stable Supply Chain Partnerships

Forge long-term agreements with reliable suppliers to lock in prices in advance or build strategic partnerships. This can reduce risks associated with price volatility.

2. Implement Dynamic Inventory Management

Develop inventory plans based on historical data and market forecasts to maintain a safe stock level of critical materials. Consider increasing inventory when prices are lower or supply is abundant to avoid production disruptions.

3. Diversify Supply Sources

Avoid over-reliance on a single supplier or region by exploring multiple sourcing options. Evaluate pricing and transportation costs from different regions to select the most cost-effective option.

4. Monitor Market Information Closely

Track raw material price trends, freight cost changes, and policy updates regularly to adjust procurement strategies accordingly. Engage with professional analysts or suppliers to gain more accurate market insights.

5. Plan Logistics in Advance

When freight costs are volatile, book shipping slots early or consider multiple transportation methods (e.g., sea freight, air freight, or multimodal transport). Optimize shipping routes to reduce unnecessary costs and minimize delays.

6. Adopt Flexible Procurement Strategies

Use a phased procurement approach to avoid purchasing the entire demand volume during market peaks, thereby reducing cost risks. Adjust procurement cycles based on market trends.

7. Explore Alternative Materials or Optimize Production Processes

Where feasible, evaluate the use of alternative materials with similar performance but lower costs. Additionally, optimize production processes to reduce dependency on certain raw materials.

By adopting these measures, buyers can better navigate market fluctuations, ensure continuity in production, and maintain cost control.

The Harmonized System (HS) Code is an internationally standardized system for classifying traded goods. For Brown Fused Alumina, the typical HS code is 28181000, which falls under the category of “artificial corundum, whether or not chemically defined.”

Importance of HS Code:

Facilitates International Trade: Ensures consistent classification across countries.

Customs Clearance: Helps in assessing duties and taxes.

Trade Analysis: Enables tracking and analysis of import/export data.

Businesses dealing in BFA should verify the HS code with their local customs authorities, as variations might occur based on specific products or regions.

Aluminum oxide manufacturers play a pivotal role in the production of brown fused alumina. They ensure quality, consistency, and innovation in the material’s production and applications.

1. Quality Assurance: They employ stringent quality control measures to meet industry standards.

2.Advanced Technology: Use modern equipment for efficient and eco-friendly production.

3.Global Reach: Many manufacturers export brown fused alumina worldwide, serving diverse industries.

4.Customization: Offer tailored products to meet specific customer needs, such as varying grain sizes or calcined variants.

By reading this blog you can learn about the top ten brown fused alumina abrasive manufacturers in China so that you can make a better choice. Top 10 Brown Fused Alumina Abrasive Grain Manufacturers in China

Brown fused alumina is indispensable in several industries:

1. Abrasives

Bonded Abrasives: Grinding wheels, sharpening stones.

Coated Abrasives: Sandpapers, polishing belts.

Loose Abrasives: Blasting media for surface preparation.

2. Refractories

Used in linings for furnaces, kilns, and reactors due to its thermal resistance.

3. Other Industrial Uses

Wear-resistant coatings.

Ceramic and high-performance material additives.

The price and availability of Brown Fused Alumina are influenced by raw material costs, production processes, and global demand. Understanding its HS code, 28181000, is crucial for international trade. Reputable aluminum oxide manufacturers play an essential role in ensuring the quality and supply of this vital material.

From abrasives to refractories, brown fused alumina continues to drive industrial progress, offering unmatched durability and versatility. Businesses and consumers alike can benefit from its properties by partnering with trusted suppliers and staying informed about market trends.